Your choice in production partnerships can make or break your project. This is especially true in precision machining, where expertise is a must. Choosing the right precision parts fabrication partner plays a critical role in the ultimate success of your product. It can have a major impact on the quality and performance of your precision machined parts, and can make or break your competitive advantage. Here, our experts will take a closer look at how precision parts fabrication can elevate quality and why Alco is the ideal manufacturing partner for you.

Explore how Alco can manufacture the ideal components for you with our comprehensive precision machining capabilities. Get in touch with us today.

The Scope of Precision Parts Fabrication

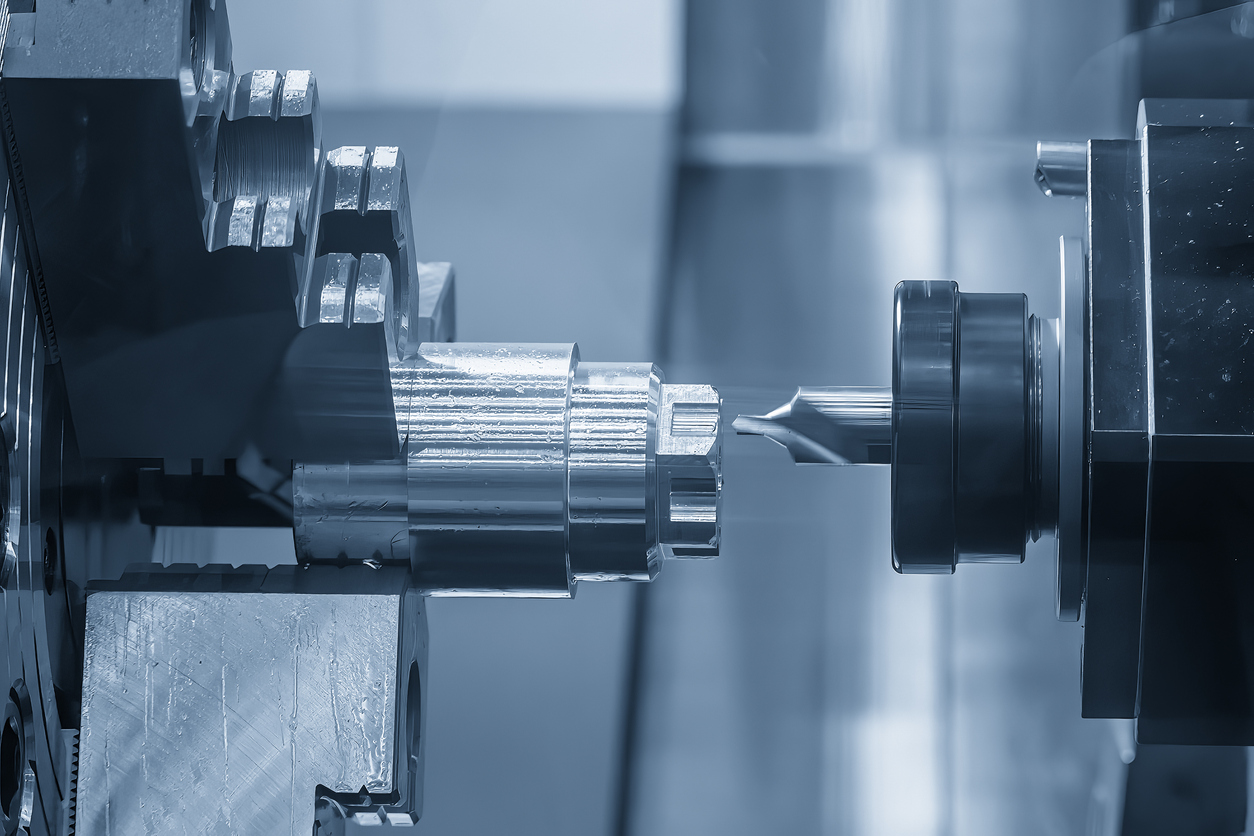

Precision machining is a broad term and encompasses many different services, including:

- Multi-spindle screw machining: Ideal for straight symmetrical fittings and other products, like nuts or barbs, multi-spindle screw machining involves multiple spindles that simultaneously perform machining operations on a workpiece. In addition to increasing precision, this manufacturing method is highly efficient, making it well-suited for high-volume production.

- CNC milling and turning: CNC milling utilizes a computer-controlled, rotating cutting tools to remove material from a workpiece, while CNC turning removes material from a workpiece by rotating the item itself. Both of these processes improve precision and dimensional accuracy.

- Swiss machining: Similar to CNC turning, Swiss machining utilizes specialized lathes to remove material from a workpiece, enhancing precision and efficiency at the same time.

There are multiple industries that rely on these manufacturing techniques, such as aerospace, medical, automotive, and electronics. These sectors require high attention to detail and precision in order to ensure peak performance.

Examining the Advantages of Precision Manufacturing

Precision parts fabrication enhances product quality by ensuring tight tolerances which reduce defects. This is especially important in critical industries like the medical or aerospace sectors where errors can be catastrophic. These manufacturing methods also enhance consistency and repeatability, and with fewer errors during the assembly process, you can expect an improved fit with the final product.

Typically, precision parts fabrication utilizes high-grade materials, which prevents potential weaknesses. That means you can expect enhanced durability and longevity, increasing the overall lifespan of the product. With improved efficiency and operation, precision machining boosts product performance and results in a faster time to market because of a reduced need for reworks. Because of reduced material waste and labor costs, this process is also more affordable. Lastly, precision fabrication is conducive to customizable designs, increasing customer satisfaction with the finished product.

Partner with Alco for Your Precision Parts Fabrication

When it comes to precision machining, there is no greater manufacturing partner than Alco. For over 50 years, we’ve been industry leaders in the precision machining world, and with our extensive capabilities and experience, you can rest assured knowing that your components will perform as needed without question.

We provide a variety of services, including multi-spindle screw machining, Swiss machining, milling and turning, and much more. We also understand the importance of proper preparation, which is why we offer tooling design and prototyping in order to ensure production goes smoothly and your components are accurate. At Alco, we are committed to producing high-quality, high-performing parts that help you maintain a competitive edge.

If you’re looking to enhance the quality of your precision parts fabrication, we can help. Connect with Alco for better precision machining now.