In modern manufacturing, high volume machining can offer many essential advantages, and the importance of consistent quality in this mass production cannot be overstated. Precision drives this consistency, which can boost the overall performance of high volume components and help you maintain your competitive advantage. Here, we will take a closer look at the role of precision in high volume machining and how Alco has the necessary expertise to manufacture high quality, reliable components.

Essential Characteristics of High Volume Precision Machining

High volume manufacturing offers many key benefits. It’s a more affordable manufacturing method because there’s a reduced need for additional set-ups. High volume production results in improved quality because it leads to consistent and reliable manufacturing. This reliability also leads to a faster time to market, helping you to save money while also maintaining your competitive advantage.

Several industries utilize high volume precision machining, such as automotive, aerospace, and medical. These markets require accurate, consistent components in large quantities, so high volume machining is the ideal solution that allows for scalability and affordability.

Precision is Key

Matching exact specifications and tight tolerances in production is incredibly important, especially in vital industries where the slightest error can impact the performance of a component. Precision ensures consistent quality by reducing variation in output, which improves fit and function. By enhancing the reliability of parts, you can also expect reduced material waste and costs.

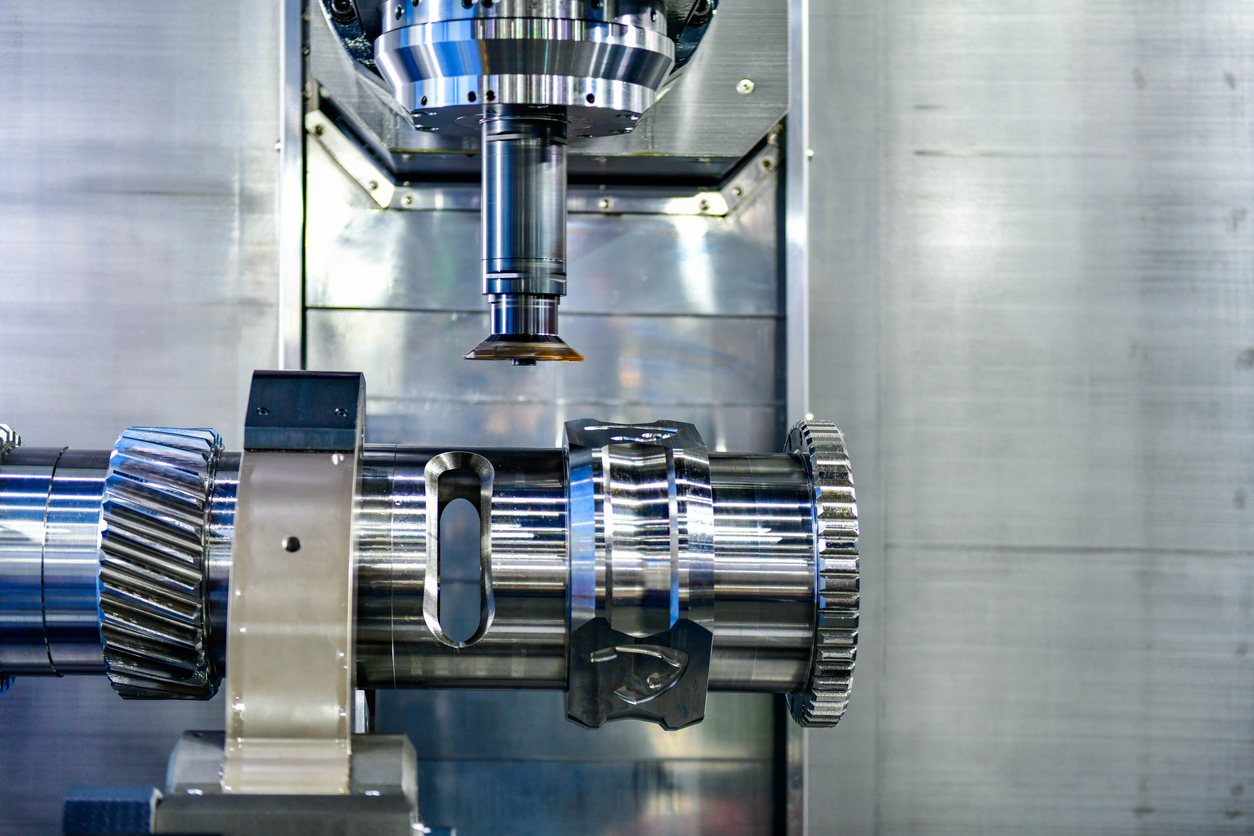

Precision high volume machining enhances process repeatability, leading to more consistency. Some common methods used in high volume machining include CNC milling and turning, Swiss machining, multi-spindle screw machining, and more. All of these processes result in highly precise and consistent components that achieve tight tolerances and can be manufactured in high volumes.

Alco is Ready to Achieve Precision at Scale

Some challenges to high volume machining include tool and machine degradation over time, material inconsistencies, and unstable environmental conditions, such as temperature. That’s why it’s so vital to ensure your precision machining partner is experienced enough to handle these difficulties with ease.

That’s where Alco can help. For over 50 years, we have been considered industry leaders in the precision machining world, and we have a wide range of capabilities that allow us to craft the ideal components for any application. We support our customers from concept to creation, with tooling design and prototyping services, as well as CNC milling and turning, Swiss machining, hydromats, and much more.

With over seven locations and a dedication to customer support, Alco’s high volume machining capabilities can reduce costs, increase customer satisfaction, and help you maintain your competitive advantage. Connect with Alco today to learn more about how we can help you.